Grenfell Tower Inquiry diary week nine: ‘All I can say is that you will be taken out for a very nice meal very soon’

This week, the inquiry heard evidence from witnesses at Harley Facades, the sub-contractor responsible for Grenfell Tower’s cladding. The witnesses were grilled about their relationships with other key members of the supply chain and their knowledge of the safety of the materials they were using on the building. Pete Apps recaps the key points.

A very nice meal

Arguably the key task for this first stage of the lengthy second phase of the inquiry is to understand how and why the team responsible ended up selecting deadly Reynobond PE 55 cladding – an aluminium composite material (ACM), which burned like petrol when ignited.

This week added a startling new facet to that story: the extent to which Harley was apparently pushing Reynobond to the exclusion of other cladding products.

This story began in on 27 September 2013 when Mark Harris and Ray Bailey, the commercial manager and managing director at Harley, met with Bruce Sounes, the lead architect, in a coffee shop in Hay’s Galleria, London Bridge, to discuss “options and costs”.

They showed Mr Sounes a brochure of its previous jobs, which included a number of high-rises clad in ACM. “Their recurring experience is that budgets force clients to adopt the cheapest cladding option: ACM,” Mr Sounes wrote in an email following the meeting.

However, Mr Sounes remained keen on zinc and asked Mr Harris to explore costs for various cladding options, particularly a product called ‘NedZinc’, which he said “could be ideal”.

But this was not what Mr Harris provided. Instead, he offered budget options composed entirely of Reynobond products. In an email, he emphasised that if the switch to ACM was made, “the saving could potentially be over £500k” and offered site visits to other blocks that had used ACM.

“Is it fair to say that you were actually pushing Reynobond ACM – or at least ACM – pretty hard?” Richard Millett QC, counsel to the inquiry, asked Mr Harris.

“We weren’t sitting there thinking anything but: ‘This is a really good product for this application and may prove a good solution for Grenfell Tower,’” he replied.

Mr Harris was then aked to get a quote for another zinc product, a Proteus panel manufactured by KME. The firm gave Mr Harris a price of £115 per square metre, but this was not what he passed on to Studio E. Instead, he gave a price of £282 per square metre, which included his own estimates for the cost of transport and fabrication. In the email to Studio E with the price, he wrote: “From a Harley selfish point of view, our preference would be to use ACM. It’s tried and tested on many Harley projects.”

Questioned, he said this was “a poor choice of words”, adding: “I was alluding to the fact there that Harley had great experience using ACM and liked using the product.”

Eventually, Mr Sounes included Reynobond ACM as an alternative when the work went out to tender and it was eventually selected.

When he got the news it was likely to be used, Mr Harris forwarded the email to Debbie French, a salesperson at Reynobond manufacturer Arconic, and Geof Blades, sales director at CEP, which would cut it to shape and sell it on.

Mr Blades responded: “All I can say is that you will be taken out for a very nice meal very soon somewhere very soon.”

Ms French added: “It’s getting exciting… thank you for your hard work and perseverance in putting Reynobond forward. I think I owe you and Geof either lunch or dinner at some point.”

“It looks from what we have been seeing so far that the relationship between the three of you was pretty cosy, to use a colloquialism. Would you accept that?” said Mr Millett.

“No, I would say it was professional, and we knew each other professionally and that was all,” replied Mr Harris.

“Were any incentives provided for you to use Alcoa and their Reynobond product over any other product made by other manufacturers?” asked Mr Millett.

“No,” said Mr Harris.

‘Did you just take it on trust from Celotex?’

Aside from questions about its role in selecting the products, Harley’s witnesses were also grilled about their knowledge of whether the products being included were safe and compliant with the regulations.

These questions were particularly pertinent in relation to the insulation, Celotex RS5000, which was used on the building despite being below the required standard of limited combustibility – a straightforward breach of the guidance.

Ray Bailey, managing director and founder of Harley, was asked about this in detail and his answers were enlightening.

He first explained that the use of combustible insulation on high-rises had become commonplace when rules on insulation performance toughened in 2009.

“Prior to 2009, every project we did had [non-combustible] Rockwool on it,” he said. As a result, he assumed combustible insulation could be used on high-rises.

“When we were asked to use Celotex on Grenfell Tower, we were of the mindset that these new special super-duper insulation products were acceptable, providing they met certain criteria,” he said.

He said he believed this first because Celotex used a phrase ‘Class 0 throughout’ to advertise its products. He said this led him to believe the product was actually of limited combustibility.

“I think this is a confusion… I think it’s quite widespread throughout the industry,” he said.

This confusion arose because Class 0 is the standard in official guidance for the external walls. It applied, before Grenfell, to the ACM cladding panels but not to the insulation, which was required to be ‘limited combustibility’ – an entirely separate standard no plastic could reach. The phrase ‘Class 0 throughout’ is essentially meaningless.

However, the apparent confusion went further than this. Celotex advertised its product as “suitable for use on buildings above 18m” and referred to a test it had passed that apparently cleared the way for its installation on high-rises, despite its combustibility.

But this test was not in a system using ACM – it was with cement fibre panels and should only have been installed in the exact combination tested. Product literature made this clear.

Mr Bailey’s evidence was that Harley had specifically asked Celotex for an assurance that the product was suitable for use on Grenfell and had been told it was.

“We had their technical sales manager in to go through the project, we sent drawings showing the application with the ACM on the building to them, and I think we carried out all possible reasonable checks,” said Mr Bailey.

“Did you just take it on trust from Celotex… Even though they had a vested interest in making sure you bought the product because they were making it and selling it?” asked Mr Millett.

“Yeah. Why… how… why would they lie to us?” replied Mr Bailey.

It is important to say that while Celotex is yet to give evidence, its opening statement makes clear that the firm did not believe it had any design responsibility for Grenfell. No emails or documents were disclosed confirming Mr Bailey’s claim that Celotex approved the use of the product for Grenfell.

‘We can control and understand what core is being used in all projects’

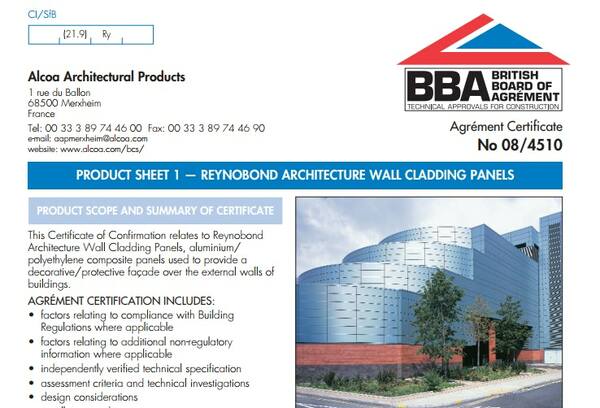

What then of the Reynobond ACM? Mr Bailey placed a good deal of weight on a British Board of Agrement (BBA) certificate (pictured) from 2008 that apparently confirmed the product had a Class 0 rating.

On the face of it, this is a reasonable argument. Government guidance required Class 0 for external surfaces of walls before Grenfell and official certification would serve as reasonable confirmation of this standard.

But there were several issues. He only read the certificate in detail in 2008 and did not specifically check it when it was sent with reference to the Grenfell project in 2014.

The certificate made disclaimers concerning colour changes, which he did not note. It also specifically noted that the products were available in a ‘fire retardant grade’ – and the only Class 0 test pass to which it referred was for this grade.

Mr Bailey said he believed the only difference for Reynobond FR ACM was that this would produce less smoke and never considered that it might be a better product for Grenfell Tower.

There was also enlightening evidence at this point relating to Arconic. In the first week of evidence, the inquiry saw an email from Ms French relating to several high-rise fires in the Middle East involving ACM. She was reassuring third-party suppliers such a disaster would not be repeated in the UK.

She said the firm could “control and understand what core is being used in all projects” and as a result “offer the right Reynobond specification including the core”.

Mr Bailey said he was “shocked” by this email and said “none of that’s been fed back down to us”.

We also caught a glimpse of a witness statement from Claude Wehrle, a senior figure at Arconic, that referred to the fact that Reynobond was testing to rock-bottom fire classification of ‘Class E’ when cut into cassette form. This was the type of panel used on Grenfell and Mr Bailey said he was “absolutely not” made aware of this testing.

‘Self-appointed spy’

Also probed, particularly with Mr Harris, was the close nature of the relationship between Harley and the eventual lead contractor Rydon.

As early as August 2013, before the project was even put up for bidding, Mr Harris – whose job was to win projects for Harley – emailed a contact at Rydon to notify them of the planned Grenfell Tower works.

“This one has ‘our’ name written all over it,” he wrote.

When Rydon was bidding against two other firms (Durkan and Mullaley) for the work in February 2014, the rivals contacted Mr Harris for some pricing information to inform their bids.

He wrote to Simon Lawrence, contract manager at Rydon: “We have opted to keep it basic and not issue a detailed programme but would be happy to do so for your good self!”

Mr Lawrence replied: “I hope you were as vague with your price with them whilst inflating it also!!”

“I don’t know what he meant by that, but I can assure you that we didn’t do any of that,” said Mr Harris.

Asked if he was acting as a “self-appointed spy” for Rydon, Mr Harris said he was being “helpful” because “we had the historic relationship with Rydon… I think you find in the world of contracting… this goes on all the time”.

‘We are not statutory compliance experts’

Pinning down exactly what Harley was responsible for doing at Grenfell Tower is made more complex because it never signed a formal contract for the works.

Instead, in July 2014, it was given a ‘letter of intent’ authorising it to carry out £30,000 of design works. By September, with no contract in place, the amount of work to be carried out under the letter was extended to the full £2.6m cladding job.

This letter therefore represents the only contractual position between Rydon and Harley, even though – for reasons unexplained – Harley did not actually sign it.

The letter’s terms made Harley responsible for the design of the facade “including relevant compliances” and referred to the main contract Rydon had signed, which included reference to various documents spelling out the potential fire risk of using combustible materials.

But when Mr Bailey was asked if this meant “the buck stopped with Harley” with regard to the safety of products and design, he insisted it did not. He said that “ultimately”, the firm was reliant on building control inspectors at the council to ensure its designs complied.

“Are you telling us that, even though Harley was a specialist cladding subcontractor with a lot of experience, particularly in relation to overcladding high-rise residential buildings, you nonetheless relied on building control to tell you whether or not the products and design complied with the statutory requirements?” said Mr Millett (pictured).

“We are not statutory compliance experts, so when we have a doubt about how something is done, we seek guidance, and building control are the experts on compliance,” replied Mr Bailey.

‘We are doomed to fail’

Neither Mr Bailey, the overall boss of Harley, nor Mr Harris, who won its jobs, worked directly on the Grenfell design or site management, so we will have to wait until next week to get more details about this. But there was some concerning evidence this week.

First, we saw an email written shortly before Harley was appointed spelling out major concern about its capacity to do the job.

“There are many items which need looking at by our proposed Grenfell House [sic] construction team, and therein lies the problem, we don’t fucking have one!!” wrote Mr Harris on 18 June 2014. “The last thing I want to do is walk away from the job… However, unless we can gear up and service it, will [sic] are doomed to fail.”

Mr Bailey says the firm responded by recruiting an initial designer and backing away from another potential job in Wembley.

But there were evidently financial pressures floating around Harley. Mr Bailey revealed the firm as it was then known – Harley Curtain Wall – went into administration in September 2015 before the job completed. The work was transferred to a dormant company he also owned, Harley Facades.

Finally, eyebrows were raised by the revelation that the project manager for the work was Ben Bailey, Ray Bailey’s 25-year-old son, who had previously only managed one project. “He has worked for the company during his school and university holidays since 2009, so he was very familiar with project management,” explained Mr Bailey Sr.

‘Quids in’

The week started with the last Rydon witness, Zak Maynard (pictured), who was taken through the company’s decision to hide the true costs of cladding savings from client Kensington and Chelsea Tenant Management Organisation (KCTMO), in order to boost its profit margin.

We discussed that in detail in a previous Grenfell diary, but Mr Maynard’s evidence was enlightening in revealing how brazenly this was discussed internally by Rydon.

In relation to the switch, he wrote: “First part of the battle now we will agree to give them 10% of the savings back and we are quids in!!”

Asked about this, he explained: “You know, if we don’t have to give them back as much as we thought, we would have more profit.”

What’s next?

The inquiry continues next week with more witnesses from Harley. A timetable of the planned run through to the end of Phase Two evidence in December 2021 has now been published.

Grenfell Tower Inquiry: week nine headlines

‘We will be quids in,’ Rydon manager says in email about Grenfell cladding switch

Rydon’s commercial manager emailed his boss to say the firm would be “quids in” as a result of savings made from switching the cladding from zinc to a deadly aluminium composite material option, the Grenfell Tower Inquiry heard today.

Grenfell cladding sub-contractor did not check drawings for compliance

The owner of the specialist cladding company that installed the deadly system on Grenfell Tower said the firm did not check whether design drawings met statutory requirements and had been “convinced” by the insulation manufacturer that its combustible insulation was suitable for high rises.

Grenfell cladding contractor ‘took it on trust’ that products complied

The cladding sub-contractor for Grenfell Tower was “confused” by basic fire standards for cladding products and “took it on trust” from the manufacturers that they were compliant, the inquiry into the fire heard today.

Manager at Grenfell sub-contractor offered ‘very nice meal’ after deal for deadly cladding secured

The commercial manager at the cladding sub-contractor employed on the Grenfell Tower refurbishment today denied promoting the deadly cladding due to a "cosy" relationship with supplier as emails revealed he was offered "very nice meal" after the deal was secured.

Grenfell Tower Inquiry phase two: weekly diaries

Module one: the refurbishment

Week one: A vivid picture of a broken industry

After a week of damning revelations at the opening of phase two of the Grenfell Tower Inquiry, Peter Apps recaps the key points

Click here to read the full story

Week two: What is the significance of the immunity application?

Sir Martin Moore-Bick has written to the attorney general requesting protection for those set to give evidence at the Grenfell Tower Inquiry. Peter Apps explains what the move means

Click here to read the full story

Week three: Architects of misfortune

This week saw the lead architects for the Grenfell Tower refurbishment give evidence to the inquiry. Peter Apps runs through the key points

Click here to read the full story

Week four: ‘I didn’t have any perception that it was the monster it’s become’

The architects continued to give evidence this week, outlining a lack of understanding of the fire risk posed by the cladding materials and its design. Nathaniel Barker reports

Click here to read the full story

Week five: ‘No adverse effect in relation to external fire spread’

As the Grenfell Tower Inquiry returns from its long absence, Peter Apps recaps the key points from a week of important evidence from the fire consultants to the refurbishment

Click here to read the full story

Week six: ‘I can’t recall any instance where I discussed the materials with building control’

Nathaniel Barker summarises what we learned from fire engineers Exova, architects Studio E and the early evidence from contractor Rydon

Click here to read the full story

Week seven: ‘I do not think I have ever worked with a contractor operating with this level of nonchalance’

Two key witnesses from contractor Rydon gave evidence this week. Peter Apps recaps some of the key points from a revealing week of evidence

Click here to read the full story

Week eight: ‘It haunts me that it wasn't challenged’

Four witnesses from contractor Rydon gave evidence this week. Lucie Heath recaps what we learned on the last week of evidence before the inquiry breaks for five weeks

Click here to read the full story

Week nine: ‘All I can say is you will be taken out for a very nice meal very soon’

This week the inquiry heard evidence from witnesses at Harley Facades, the sub-contractor responsible for Grenfell Tower’s cladding. Peter Apps recaps the key points

Click here to read the full story

Week 10: ‘As we all know, ACM will be gone rather quickly in a fire!’

As the Grenfell Tower Inquiry entered its 10th week, Jack Simpson recaps the key points from a week of important evidence from the refurbishment’s cladding contractor

Click here to read the full story

Week 11: ‘Did you get the impression Grenfell Tower was a guinea pig for this insulation?’

With witnesses from the cladding subcontractor, the firm which cut the deadly panels to shape and the clerk of works which inspected the job giving evidence this was week full of revelations. Peter Apps recaps the key points

Click here to read the full story

Week 12: ‘Would you accept that was a serious failing on your part?’

With the surveyor who inspected Grenfell Tower for compliance giving evidence, this was a crucial week from the inquiry. Dominic Brady and Peter Apps report

Click here to read the full story

Week 13: ‘Value for money is to be regarded as the key driver for this project’

With consultants to Kensington & Chelsea Tenant Management Organisation (KCTMO) giving evidence, attention at the Grenfell Tower Inquiry turned for this first time to the actions of the TMO and the council. Peter Apps reports

Click here to read the full story

Week 14: ‘Did it not occur to you at this point that your budget was simply too low?’

This week, for the first time in phase two, the inquiry heard from Kensington & Chelsea Tenant Management Organisation, the landlord that oversaw the fatal refurbishment of Grenfell Tower. Lucie Heath reports

Click here to read the full story

Week 15: ‘Have you ever informed the police that you destroyed documents relevant to their investigation?’

Witnesses from the Kensington and Chelsea Tenant Management Organisation (KCTMO) gave evidence for a second week, which began with a shocking revelation about withheld and destroyed evidence. Peter Apps recaps

Click here to read the full story

Week 16: ‘I conclude this was very serious evidence of professional negligence’

This week saw members of Kensington & Chelsea Tenant Management Organisation finish giving evidence, before the inquiry’s expert witnesses took the stand to make some highly critical assessments of the work they had seen before and during the refurbishment of Grenfell Tower. Jack Simpson recaps

Click here to read the full story

Grenfell Tower: a timeline of the refurbishment

Following the conclusion of module one of the Grenfell Inquiry’s second phase, Peter Apps presents a timeline of the key moments during the fatal refurbishment of the west London tower block

Click here to read the full story

Module two: the cladding products

Week 17: ‘It’s hard to make a note about this because we are not clean’

The start of the second module of the Grenfell Tower Inquiry phase two came with some huge revelations about the companies that sold the products used in the cladding system. Peter Apps reports

Click here to read the full story

Week 18: ‘It was just reckless optimism wasn't it?’

As the inquiry began cross-examining witnesses for the second module of its phase two work, the picture surrounding just how Grenfell Tower ended up wrapped in such dangerous materials became a little clearer. Nathaniel Barker was keeping an eye on proceedings

Click here to read the full story

Week 19: ‘And that was intentional, deliberate, dishonest?’

The Grenfell Tower Inquiry this week heard the shocking story of how the insulation manufacturer “manipulated” official testing and marketed its product “dishonestly”. Peter Apps tells the story

Click here to read the full story

Week 20: ‘We were outed by a consultant who we then had to fabricate a story to’

This week the inquiry investigated the actions of Kingspan – the manufacturer of one of the insulation products used in the tower’s cladding system. Dominic Brady reports

Click here to read the full story

Week 21: ‘It’s there in black and white isn't it? We see a complete absence of any consideration of life safety’

The story of insulation giant Kingspan’s testing and marketing of its combustible insulation for high rises was unpacked in minute detail this week. Peter Apps reports

Click here to read the full story

Week 22: ‘All we do is lie in here’

In the third week of evidence from insulation giant Kingspan, the inquiry continued to uncover shocking details about the firm’s behaviour both before and after the Grenfell Tower fire. Lucie Heath reports

Click here to read the full story

Week 23: ‘That would have come as an earthquake to you at the time, would it not?’

This week the inquiry took its deepest dive yet into the inner workings of the cladding manufacturer whose product has been blamed for the terrible spread of fire up Grenfell Tower. Nathaniel Barker reports

Click here to read the full story

Week 24: ‘Do you accept that Test 5B was Arconic's deadly secret’

The president of the firm that made and sold the cladding panels installed on Grenfell Tower was asked to account for the apparent concealment of “disastrous” fire tests on the product this week. Peter Apps reports

Click here to read the full story

Week 25: ‘This is quite an incredible list of omissions and missed instances, isn’t it?’

This week the Grenfell Tower Inquiry heard its first witnesses from the Building Research Establishment (BRE) - the testing house which carried out key fire tests on the Kingspan and Celotex insulation products which were later used on Grenfell Tower. Peter Apps reports.

Click here to read the full story

Week 26: 'You were taking an enormous risk, weren't you?'

Week 26 at the Grenfell Tower Inquiry was a key moment in understanding how dangerous products used on the tower came to be accepted by industry professionals. Dominic Brady reports

Click here to read the full story

Week 27: ‘What will happen if one building made out [of] PE core is in fire and will kill 60 to 70 persons?’

The most explosive evidence this week at the Grenfell Tower Inquiry came from those who did not attend, as the evidence which would have been presented to Arconic witnesses was displayed in their absence. Peter Apps reports

Click here to read the full story

Week 28: ‘This is a serious safety matter’

This week the Grenfell Tower Inquiry zeroed in on the British Board of Agrément, the body that produced “misleading” certificates which inspired trust in both the cladding and insulation used on the tower. Lucie Heath reports

Click here to read the full story

Week 29: ‘Is it true that Kingspan’s position… was to do its best to ensure that science was secretly perverted for financial gain?’

The final week in this section of the Grenfell Tower Inquiry primarily examined the attempts by insulation manufacturer Kingspan to lobby government after the fire. Peter Apps reports

Click here to read the full story

How the products used in Grenfell Tower's cladding system were tested and sold

As the section of the Grenfell Tower Inquiry examining how the products used in the cladding system were tested, marketed and sold comes to a close, Peter Apps summarises what we have learned about each of the products included in the system

Click here to read the full story

Module Three: the management of the tower

Week 30: ‘There is certainly a high probability that in the event of a fire the whole building can become an inferno’

The focus of the inquiry shifted this week to the actions of the social housing providers responsible for maintaining Grenfell Tower. Pete Apps recaps what we learned

Click here to read the full story

Week 31: ‘If we cannot get out people will die’

This week saw the former residents of Grenfell Tower enter the witness box to tell of their experiences attempting to raise complaints with the council and its managing agent. Pete Apps reports

Click here to read the full story

Week 32: ‘Let's hope our luck holds and there isn't a fire’

This week saw the return of the landlord of Grenfell Tower, Kensington and Chelsea Tenant Management Organisation (KCTMO), as senior staff members attempted to explain how vital fire safety protections at the block were allowed to fall into disrepair. Lucie Heath reports

Click here to read the full story

Week 33: ‘Isn't that a serious gap in the scope of a policy meant to safeguard vulnerable people?’

A slightly disjointed week at the Grenfell Tower inquiry saw further evidence from staff at building manager Kensington and Chelsea Tenant Management Organisation (KCTMO) interspersed with the views of a cladding expert. Peter Apps reports

Click here to read the full story

Week 34: ‘Some members of the community are doing their best to spread false information’

Jack Simpson covers all the major revelations from the past week of evidence at the Grenfell Inquiry, including evidence from Laura Johnson, director of housing at the Royal Borough of Kensington and Chelsea.

Click here to read the full story

Week 35: ‘I really didn’t like the champagne’

This week the Grenfell Tower Inquiry saw council witnesses, including former deputy leader Rock Feilding-Mellen and leader Nicholas Paget-Brown, questioned about their role in the story for the first time. Peter Apps reports

Click here to read the full story

Week 36: ‘Is that not a very incurious approach for a fire risk assessor?’

This week the Grenfell Tower Inquiry scrutinised the work of Carl Stokes, the man hired to carry out fire risk assessments for the block. Nathaniel Barker reports

Click here to read the full story

Week 37: ‘In giving that advice, weren’t you acting beyond your knowledge and expertise?’

A curtailed week at the Grenfell Tower Inquiry saw fire risk assessor Carl Stokes grilled over advice he gave regarding the tower’s cladding. Peter Apps reports

Click here to read the full story

Week 38: ‘Well it’s a bit more than that, isn’t it. He’s suggesting that you tell the LFB a lie’

The inquiry heard the mammoth cross-examination of KCTMO’s health and safety manager Janice Wray this week. Peter Apps reports

Click here to read the full story

Week 39: ‘What you said there was a grotesque understatement’

This week the inquiry continued to hear from former employees of Kensington and Chelsea Tenant Management Organisation, as well as two employees from the London Fire Brigade. Lucie Heath reports

Click here to read the full story

Week 40: ‘An exercise in concealment and half-truth’

Former KCTMO chief executive Robert Black gave his evidence to the inquiry this week and was asked to account for the various failures described over the previous six weeks. Peter Apps and Nathaniel Barker report.

Click here to read the full story

Week 41: ‘We should do nothing. This is not the sort of website we should be responding to’

This week saw the return of Robert Black, chief executive of Kensington and Chelsea Tenant Management Organisation (KCTMO), before the inquiry turned its attention to the defective smoke control system in the tower. Dominic Brady reports

Click here to read the full story

Week 42:‘They would leak as much as they leaked. They were what they were’

The Grenfell Tower Inquiry continued its in-depth investigation of the tower’s non-compliant smoke control system this week, with evidence from the various contractors involved in delivering it. Pete Apps reports

Click here to read the full story

Week 43:‘Contractors at the time were not generally aware of the importance of leaving holes unsealed’

This week the inquiry focused on two of the more overlooked areas of the Grenfell Tower fire, with evidence focusing on the gas pipelines and lifts within the west London block. It was a packed week, with five witnesses giving evidence. Jack Simpson reports

Click here to read the full story

Week 44:‘I've never seen a fully compliant firefighting lift in any local authority building, to this day actually’

This week the inquiry turn the focus onto the building’s defective lifts, with evidence from an expert, contractors who worked on them and a former engineer at KCTMO. Pete Apps reports.

Click here to read the full story

Week 45: ‘Don’t you find all this rather a surprising debate, given that the Equality Act was passed in 2010?’

The inquiry heard from expert witness Colin Todd this week, who gave his views about the work of risk assessor Carl Stokes as well as answered questions about his own guidance. Peter Apps and Nathaniel Barker report

Click here to read the full story

Week 46: ‘I think I've been very, very clear that is completely wrong’

This week the inquiry heard further expert evidence about fire risk assessor Carl Stokes’ actions, as the section of its work covering the management and maintenance of the tower concluded. Peter Apps reports

Click here to read the full story

Six key failures in the way Grenfell Tower was managed before the fire

Peter Apps recaps some of what we have learned about the actions of the Royal Borough of Kensington and Chelsea (RBKC) and Kensington and Chelsea Tenant Management Organisation (KCTMO) in the years before the fire.

Module one and two closing statements

Week 47: ‘An unedifying spectacle’

After a week of closing statements from the core participants involved in modules one and two, Lucie Heath recaps the key arguments of each group

Click here to read the full story

Module five: the fire brigade

Week 48: ‘They knew, and lives could and should have been saved’

The phase of the Grenfell Tower Inquiry examining the actions of the London Fire Brigade in the years before the fire kicked off this week with some major revelations. Peter Apps reports

Click here to read the full story

Week 49: ‘I'm not sure we've always taken every opportunity to learn as an organisation’

How the London Fire Brigade acted upon lessons from incidents in the years before the Grenfell Tower disaster came under the microscope this week at the public inquiry. Nathaniel Barker reports

Click here to read the full story

Week 50: ‘There is a culture in LFB that is very conservative. I think there is great comfort in what is familiar’

This week the inquiry heard how the London Fire Brigade (LFB) elected not to issue warnings about dangerous cladding before Grenfell and a detailed examination of its policy for checking high risk buildings. Pete Apps reports.

Click here to read the full story

Week 51:‘We teach firefighters to expect building failure’

An unusually brief week of evidence at the Grenfell Tower Inquiry explored how a fire service neighbouring London was taking a different approach to tackling blazes in high rises. Nathaniel Barker reports

Click here to read the full story

Week 52: ‘I actually think that there is a measure of incompetence at all levels’

Expert evidence concluded the current section of the inquiry with some stinging criticism of the London Fire Brigade (LFB). Pete Apps and Grainne Cuffe report.

Click here to read the full story

Module six: fire services

Week 53: ‘They make for chilling reading and harrowing listening’

The inquiry’s investigation into central government began this week with lawyers setting out their view on how and why firefighting policies failed. Peter Apps and Lucie Heath report

Click here to read the full story

Week 54: ‘Our consideration of evacuation at this time was something of a blind spot’

The development of policy on ‘stay put’, both nationally and for London, occupied the attention of the inquiry this week. Peter Apps reports

Click here to read the full story

Week 55: ‘My review is pretty scathing!’

In a week that included the 200th day of evidence in phase two of the inquiry, attention turned to the London Fire Brigade’s control room. Lucie Heath reports

Click here to read the full story

Week 56: ‘Why didn't we thump the table harder’

This week, the control room at the London Fire Brigade was examined further – both before and after the fire. Pete Apps and Lucie Heath report

Click here to read the full story

Week 57: ‘It was worse than slow, it was sluggish’

Former London Fire Brigade (LFB) commissioner Dany Cotton was the star witness this week, as the inquiry continued to delve into the brigade’s knowledge and training before the Grenfell Tower fire. Jack Simpson, Grainne Cuffe and Pete Apps report

Click here to read the full story

Week 58: ‘I don't think we deserve to ask for trust until we demonstrate different outcomes’

A current and former commissioner of the London Fire Brigade (LFB) wrapped up the inquiry’s investigation into the actions of the brigade before the fire. Grainne Cuffe and Peter Apps report.

Module six: testing and government

One of the major scandals of our time: key revelations as the Grenfell Tower Inquiry turns to government

The government was accused of “covering up” the risks of dangerous cladding as its “unbridled passion for deregulation” left it a “junior party” to the construction industry as the latest phase of the public inquiry opened today. Peter Apps summarises some of the main points

Click here to read the full story

Week 59: ‘Recent tests have apparently shown it continued to burn for 20 minutes after the flame was taken away’

After shocking opening statements, the Grenfell Tower Inquiry turned its attention to the work of Local Authority Building Control. Pete Apps reports

Click here to read the full story

Week 60: ‘You could have an exact repeat of the Dubai fire in any number of buildings in London’

The Grenfell Tower Inquiry turned its attention to the work of the National House Building Council this week, with shocking revelations about the extent of the warnings issued to central government before the fire. Peter Apps reports

Click here to read the full story

Week 61: ‘Mistakes are meant for learning, not repeating’

In the first hearings of the new year, the Grenfell Tower Inquiry heard closing statements from the firefighting section of phase two. Lucie Heath reports

Click here to read the full story

Week 62: Did it ever occur to you that this act of collaboration was, in one sense, corrupting?

The Grenfell Tower Inquiry returned to the work of the National House Building Council (NHBC) this week, with a new shocking revelation about the government’s actions in the immediate aftermath of the fire. Peter Apps reports

Click here to read the full story

Week 63: ‘It came after the general move to deregulation. So more regulation was not welcome’

The government’s focus on deregulation before the Grenfell Tower fire was placed in the spotlight this week with a series of shocking revelations about its failure to amend fire safety guidance. Pete Apps and Grainne Cuffe report

Click here to read the full story

Week 64: ‘I didn’t think ACM would be suitable for use in any high-rise buildings. I don’t think anyone did’

This week, the Building Research Establishment’s Dr Sarah Colwell gave more than three days of evidence, with some huge revelations about what was known about the dangers of aluminium composite material years before the fire and the mass confusion over the government’s building regulations. Peter Apps and Jack Simpson report

Click here to read the full story

Week 65: ‘Unless the government does something now about ACM panels, people will die’

Further evidence from the Building Research Establishment and the first government witnesses added new depth to our understanding of how warnings were missed before the Grenfell Tower fire. Peter Apps reports

Click here to read the full story

Week 66: ‘Was there a cover-up?’

The latest evidence from the Grenfell Tower Inquiry tracked the government’s failure to act on fire safety warnings right up until the months before the fire. Peter Apps and Grainne Cuffe report

Click here to read the full story

Week 67: ‘When exposed to a fire, the aluminium melts away and exposes the polyethylene. Whoosh!’

This week the inquiry heard disturbing new evidence about the failure of senior government officials to act on warnings about dangerous cladding in the years before the Grenfell Tower fire. Peter Apps reports

Click here to read the full story

Week 68: ‘Can we agree that was a pretty dangerous thing to have, all this falling on one man’s shoulders?’

Three senior civil servants gave evidence this week, including the official who had responsibility for building regulations guidance on fire safety in the years before Grenfell. Peter Apps, Lucie Heath, Stephen Delahunty and Grainne Cuffe report

Click here to read the full story

Week 69: ‘It was just unthinkable. You had the makings here of a crisis you could not comprehend’

This week, civil servant Brian Martin gave his long-awaited evidence to the Grenfell Tower Inquiry. Peter Apps reports

Click here to read the full story

Week 70: ‘Show me the bodies’

An important week at the Grenfell Tower Inquiry saw a dramatic conclusion to the mammoth cross-examination of civil servant Brian Martin, as well as the first politicians. Peter Apps and Lucie Heath report

Click here to read the full story

Week 71: ‘I have changed my schedule to fit this in. I do have an extremely busy day meeting people’

Three politicians who were responsible for building regulations before Grenfell appeared before the inquiry this week, including the former communities secretary Eric Pickles, who responded to the coroner’s letter following the Lakanal House fire. Peter Apps and Lucie Heath report

Click here to read the full story

Module Four: aftermath

Week 72: 'The system isn't broken. It was built this way'

This week the inquiry turned to the shocking story of the lack of support for bereaved and survivors in the immediate aftermath of the Grenfell Tower fire. Peter Apps, Lucie Heath, Grainne Cuffe and Jack Simpson report

Click here to read the full story

Week 73: ‘Most people would regard that as hopeless’

This week, the Grenfell Tower Inquiry heard about the Royal Borough of Kensington and Chelsea’s chaotic response in the immediate aftermath of the blaze, from the staff responsible for it. Pete Apps, Stephen Delahunty and Grainne Cuffe report

Click here to read the full story

Week 74: ‘Do you agree that RBKC was ill-prepared and incapable to meet its duties’

This week, Nicholas Holgate, former chief executive of the Royal Borough of Kensington and Chelsea, was grilled on his failure to hand over control of the aftermath of the fire, despite the borough’s lack of capacity. Peter Apps reports

Click here to read the full story

Week 75: ‘It still shocks me to the core that that’s how we treat our citizens in this country’

This week the inquiry heard witnesses from the housing management body discuss their role in the aftermath of the Grenfell Tower fire, followed by a range of witnesses from other organisations which supported the response. Peter Apps and Grainne Cuffe report

Click here to read the full story

Week 76: ‘I fear this will become our New Orleans’

This week the inquiry heard from central government figures and members of the London-wide emergency response arrangements. Peter Apps and Grainne Cuffe report

Click here to read the full story

Week 77: ‘The planning wasn’t done and there was nothing for us to be drawing on’

The Grenfell Tower Inquiry’s examination of the aftermath of the fire concluded with witnesses from central government. Peter Apps reports

Click here to read the full story

Module seven: expert evidence and closing statements

Week 78: ‘The abandonment of the ‘stay put’ strategy for high-rise residential buildings is essential’

This week the Grenfell Tower Inquiry heard a range of expert witnesses discuss their reports. Peter Apps and Grainne Cuffe report

Click here to read the full story

Week 79: ‘You could argue the system was created to enable people to circumvent the rules’

The Grenfell Tower Inquiry continued to hear expert evidence this week, with two senior figures in the world of fire safety academia criticising the government’s approach before and after the blaze. Peter Apps and Grainne Cuffe report

Click here to read the full story

Week 80: ‘The evidence points to wilful blindness and complacency towards safety’

As the inquiry moves into its final stages, lawyers for the key players gave statements about the evidence surrounding central government. Peter Apps reports

Click here to read the full story

Week 81: ‘This is Islamophobia. It’s racism. It is the elephant staring back at us in the room’

This week, closing statements covering the aftermath of the fire delivered a shocking new revelation and an expert toxicologist gave his views on the causes of the deaths. Peter Apps reports

Click here to read the full story

Module eight: further evidence relating to the deceased

Week 82: ‘Their chance to hear about the circumstances in which their loved ones died is the culmination of five years of waiting’

The Grenfell Tower Inquiry moved into its final module this week, with evidence relating to the circumstances in which the victims died. Peter Apps reports

Click here to read the full story

Week 83: ‘They died together as they lived: caring for one another’

A second week of evidence relating to the circumstances in which the victims of the fire died delivered more heartbreaking stories about their final moments. Peter Apps recaps

Click here to read the full story

Week 84: ‘Every decision affects someone who is an adored child, a beloved sister, a respected uncle, a needed mother’

The final week of oral evidence for the Grenfell Tower Inquiry’s second phase contained more heartbreaking evidence about the deaths in the tower. Peter Apps reports

Click here to read the full story

Closing statements

Week 85: ‘The merry-go-round turns still, the notes of its melody clearly audible in the last few days’

The Grenfell Tower Inquiry returned this week for closing statements from lawyers representing the bereaved and survivors and the various parties under scrutiny for the fire. Pete Apps reports.