Offsite manufacture overview

For the second year, Inside Housing partners with LHC on a review of offsite manufacturing. Claire Read analyses the responses. Picture by Getty

In association with:

In one of their last actions before rising for the summer recess, members of the House of Lords offered a clear message to anyone grappling with the challenge of how to deliver more homes. On 19 July, peers on the Science and Technology Select Committee published the results of their inquiry into offsite manufacture (OSM)for construction. Their conclusion was unequivocal: “There are clear and tangible benefits… which make a compelling case for its widespread use.”

The message is not a new one. Most recently, the 2016 Farmer Review contended offsite was a vital remedy to the problems of unmet housing need and the construction skills shortage. So are social landlords actively adopting modern methods of construction to help address the sector’s challenges?

Minority pursuit

For the second year running, Inside Housing has partnered LHC on a survey to tease out some answers to that complicated question. Some 230 individuals have responded to the 2018 survey, drawn from housing associations, ALMOs, local authority and other relevant organisations such as consultancies and construction firms.

The immediate conclusion is that active use of offsite construction remains something of a minority pursuit. Only 41% of respondents say their organisation either currently uses such methods or has previously done so.

That said, the figures demonstrate a small uptick in those planning to use offsite construction for homes to be delivered within the next 12 months. In 2017, only 41% of respondents said they were planning to employ these construction methods in the coming year. Now, however, 43% of respondents plan to use offsite during the next 12 months.

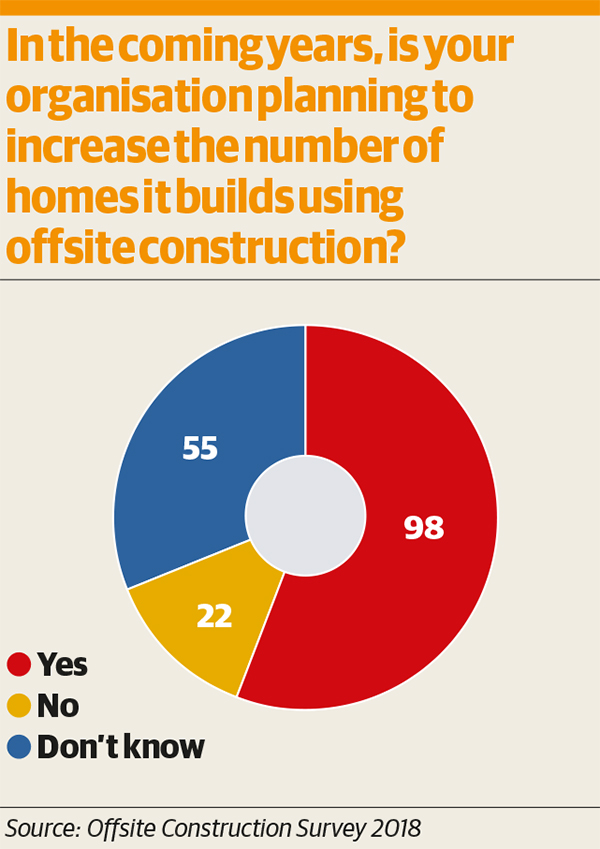

And asked about longer-term plans, our respondents indicate an expectation of greater use of offsite construction technologies such as volumetric, panellised and hybrid. More than half – 56% – say their organisation is planning to increase the number of homes it builds using such methods in the coming years.

There is a caveat, however. For the majority of respondents, any use of offsite construction will still be at relatively small scale. Most say their organisation will only employ offsite for 1% to 10% of homes delivered in the next 12 months.

It is certainly the position espoused by Brian Ham, executive director of development at Home Group. He reports offsite is still in a “test phase” at the organisation. “We’re keen to experiment and learn,” he says. “But we intend to progress patiently to ensure we get the right message and supplier.”

Such pronouncements do not come as a surprise to Tony Woods, technical manager at LHC. He says there is no doubt there has been “a general move” in the direction of offsite construction. He adds: “But the survey results imply to me that most people are still just dipping their toe in the market and looking at doing pilot studies without really committing.

“I think people are very conservative and I think most of the public sector tends to follow rather than lead on this. So they’ll keep doing pilots until someone really blazes the trail.”

Our survey respondents have clearly indicated the areas in which reassurance is needed. For instance, while one development professional at a housing association reports clear plans to use offsite to deliver homes, “it will be a small percentage of the total until we can be confident about quality, robustness and fire-proofing”.

It is notable that 45% of our respondents say the primary reason their organisation is planning to increase offsite construction is to speed up delivery. But some fear the desperate need to start building homes is leading to a lack of focus on longer-term viability.

As one individual working in development at a housing association puts it: “The most important thing as long-term landlords is that we have well-built assets. There is too much obsession with speed in this debate – driven by people wanting a ‘quick fix’. The emphasis should be on quality and long-term robustness.”

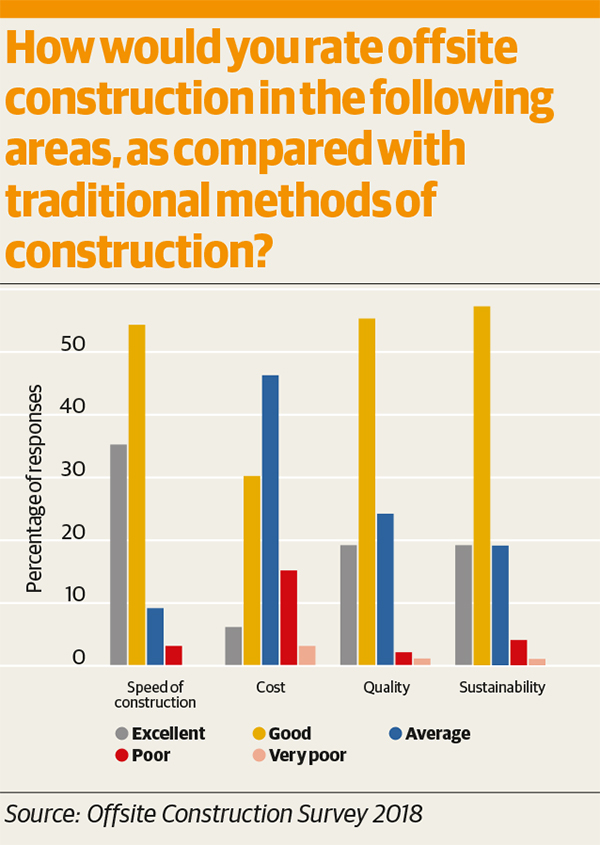

Indeed, our survey results imply the speed argument has already convinced most. A striking 89% of those who answered our survey rate offsite as ‘excellent’ or ‘good’ on speed of construction when compared to more traditional methods. The verdict on cost benefits is more mixed, with only 6% considering offsite excellent on this metric, 30% considering it good and 46% average.

Turnkey solution

One researcher in the sector tells us offsite “certainly brings speed and cost benefits”. But the individual continues: “The jury is out on quality and sustainability. There are examples of good quality but focus on reducing costs has [meant] as-yet untested impact on quality and sustainability in the longer term.”

There are concerns too regarding the ability of manufacturers to provide a turnkey solution. As one respondent working in procurement at an ALMO puts it, “the risk is in the coordination of the groundworks/foundation package and the delivery of the offsite construction. Companies don’t seem to offer the whole package.”

LHC’s Mr Woods says: “We’ve found over the past few years that clients want a turnkey solution [from offsite manufacturers]. They just want to go to one person and say, ‘Right, build the house – do all the work’. And you’ve still got a disconnect, I think, with some people who say they just want to manufacture whereas clients want somebody who can build houses.”

For Allan Fisher, director of development and assets at Nottingham Community Housing Association, there is also the need to ensure offsite providers are capable of operating at scale. “Too many OSM factories seem to be popping up all saying they need the volume. It would be better suited to a combined regional sector approach with a small number of suppliers who can deliver based on volume available and can gain the necessary warranties and accreditations required for multi-tenure programmes.”

It’s a comment which underscores the main concern many respondents highlight – the relative immaturity of the market and a lack of rationalisation. But this should not conceal an overall view that these methods of construction do offer a viable way forward for the sector. The chair of the organisation representing London’s largest housing associations is certainly convinced greater use of offsite is an inevitability.

“The industry hasn’t yet reached the tipping point where offsite is lower cost than traditional for most residential developments,” says Paul Hackett, who is the chief executive of Optivo. “However, it’s just a question of time. Now is the time for HAs to gear [up], with partnerships as the best way to learn.”